SprutCAM Robot at Chinese Tik-Tok

Our resellers keep up with the times and master all possible social networks and platforms.

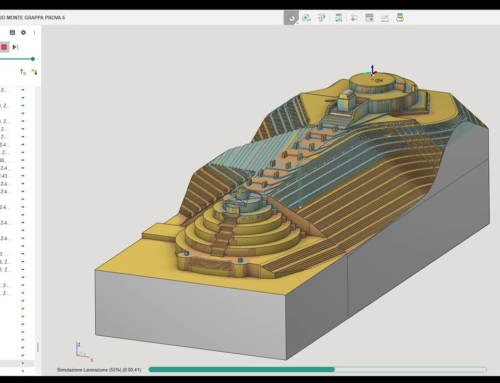

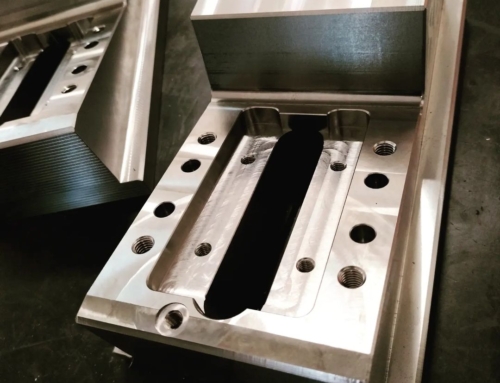

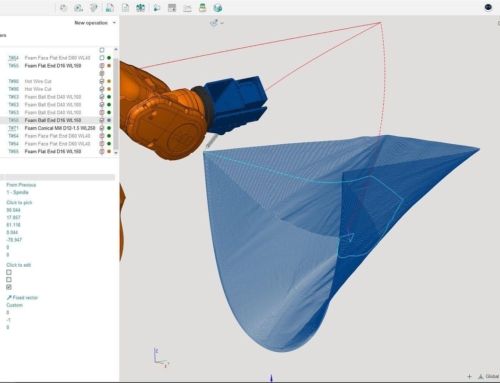

In this video, we have compiled a selection from the Chinese Tik-Tok from our partner from China on the SprutCAM Robot topic.

Find more Chen’s posts on Facebook.