Our flagship products

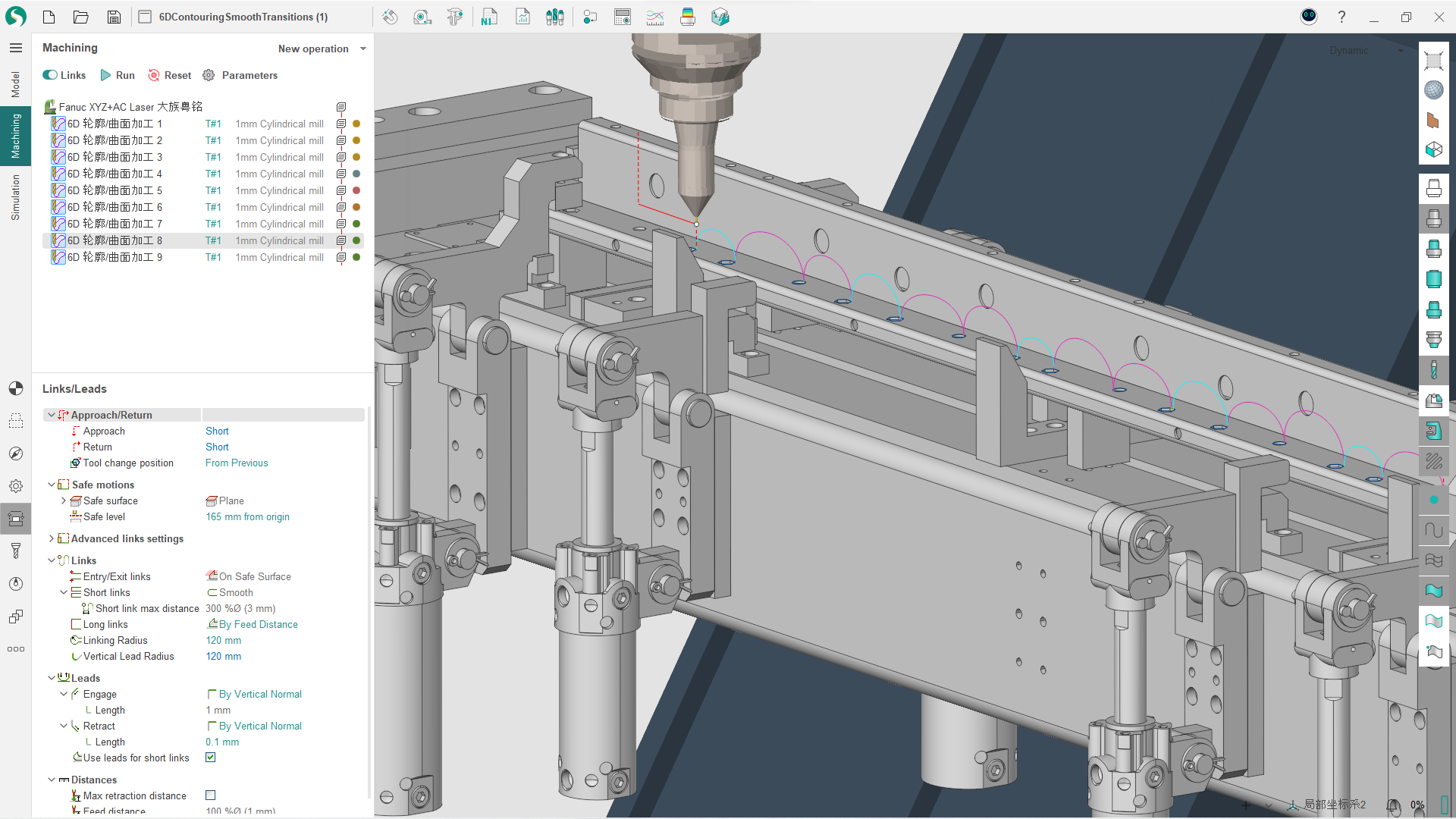

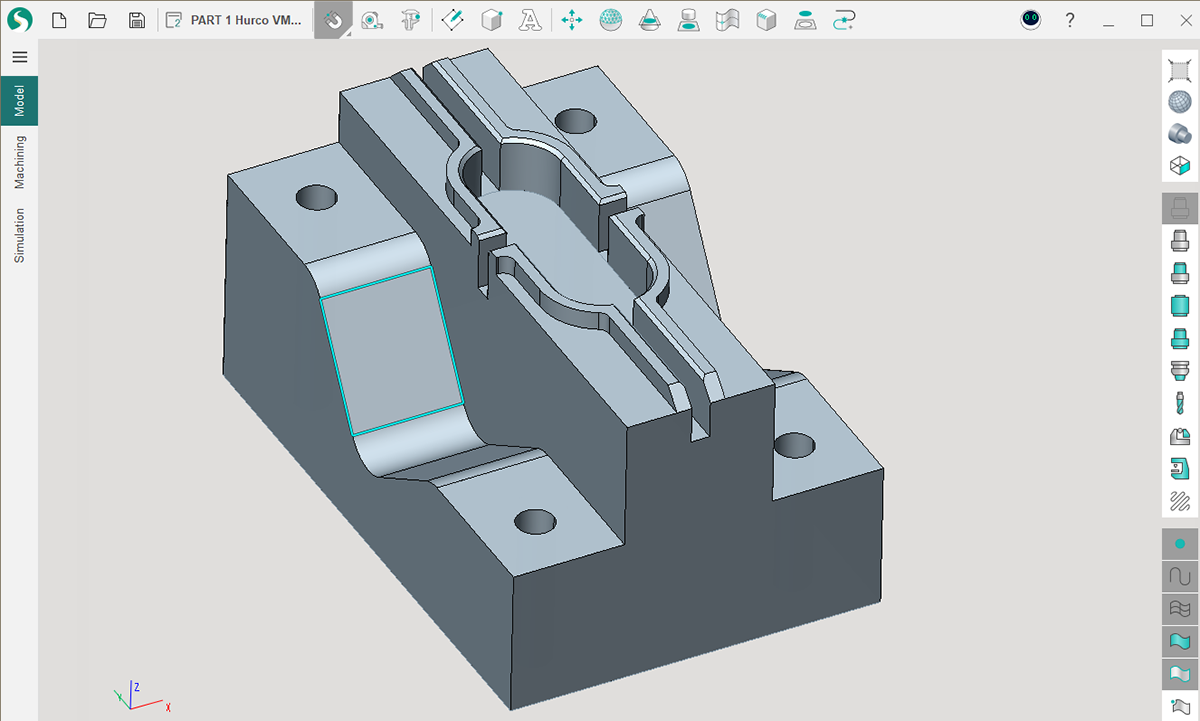

Meet SprutCAM X 17

We are proud to present the newest, most powerful, and feature-rich version of SprutCAM X in the entire history of our software product.

New version highlights:

- multi-project workflow

- project snapshots

- machine setups

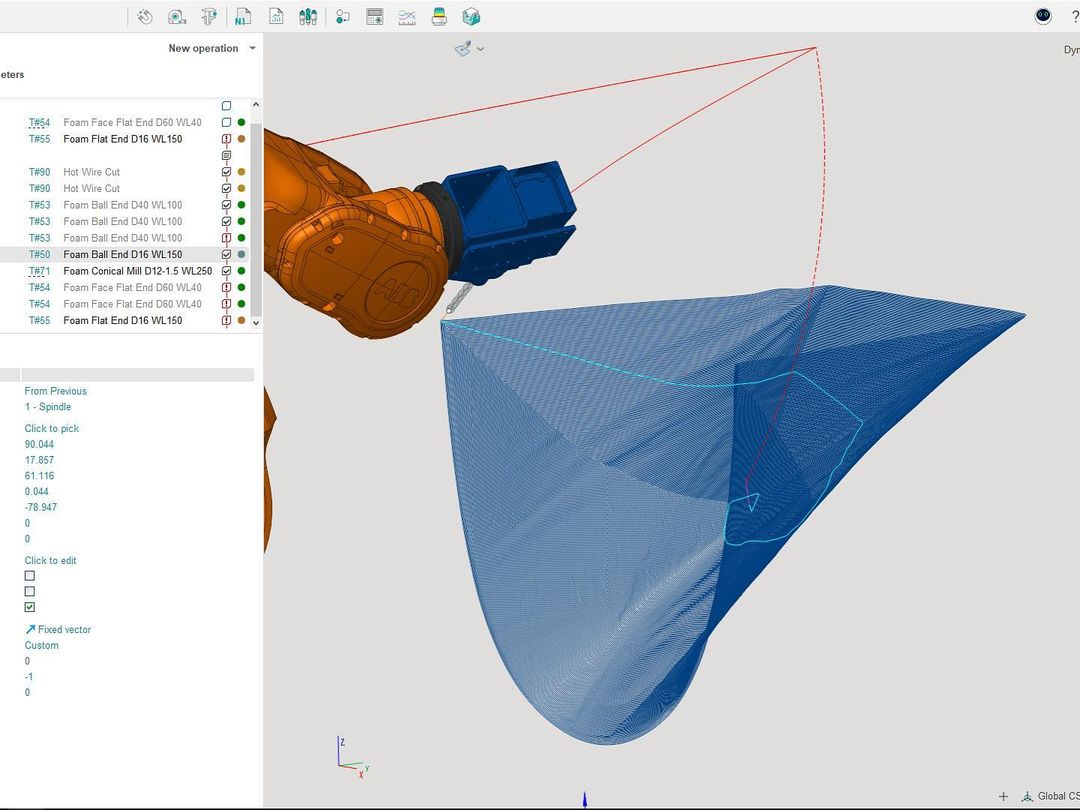

- new and enhanced machining technologies

- revamped CAD module

- AI assistant

Ready to embark on your SprutCAM X journey?

Select your preferred path

About SprutCAM Tech

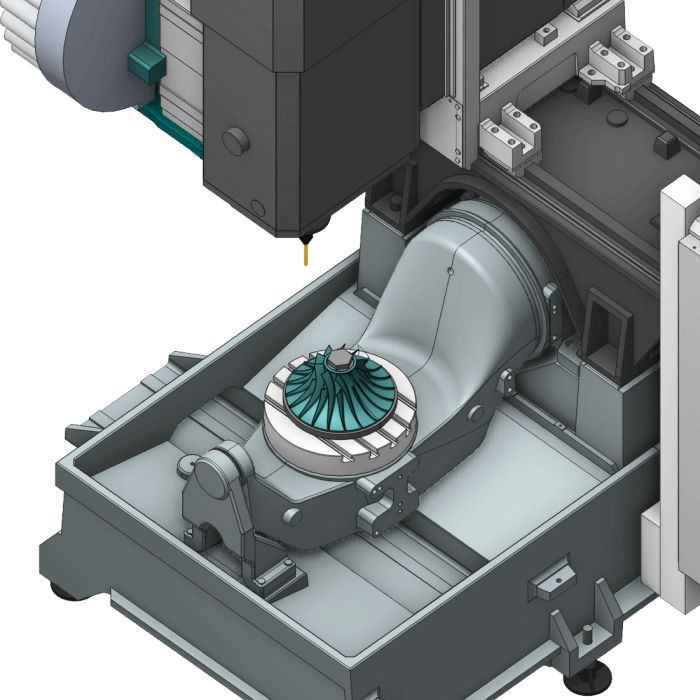

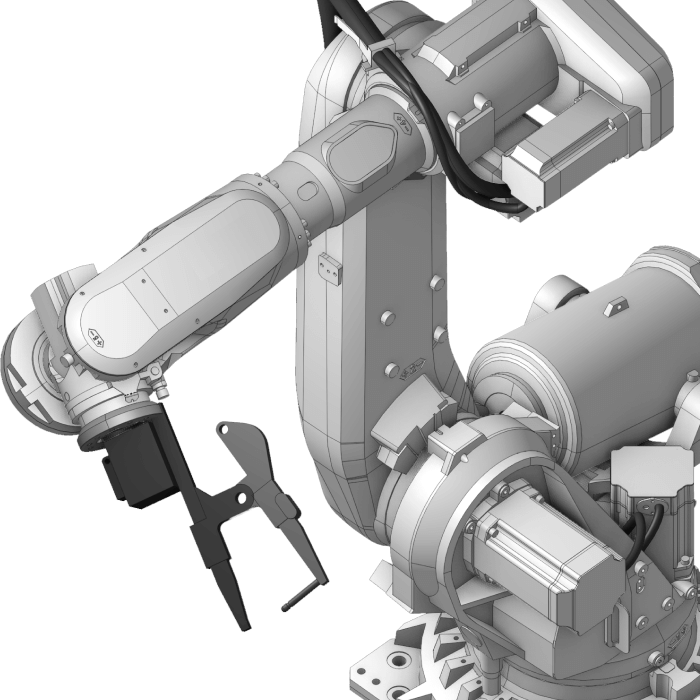

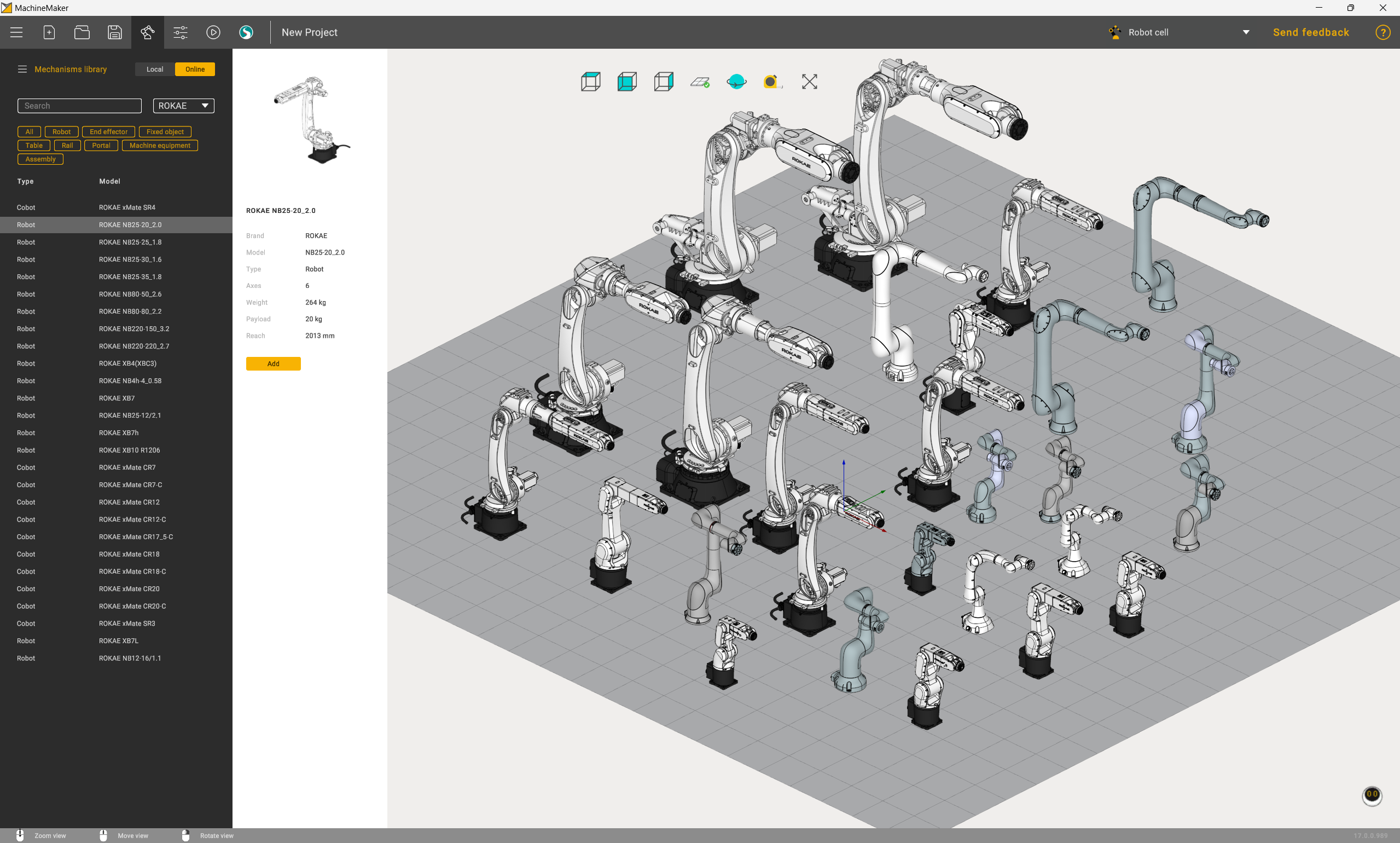

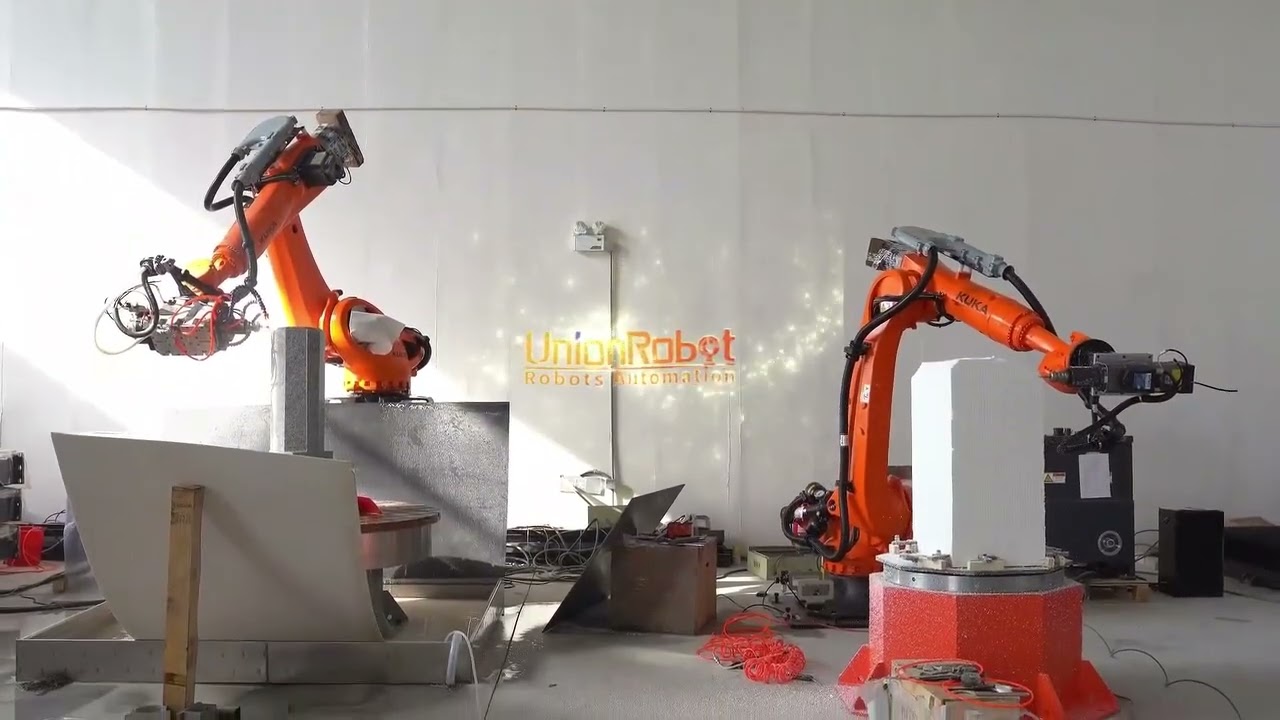

Inspired by nature, we create powerful software for programming CNC machines and industrial robots. By deeply understanding the needs of engineers, we design a user-friendly interface that simplifies and speeds up shop floor tasks.

Our mission is to create a natural CAD/CAM environment for CNC machines and industrial robot programming.

Our vision is to create software that enables manufacturers to seamlessly transition from CAD to finished parts with the fastest turnaround time in the industry.